Heavy Load Double Beam Gantry Crane

- VOHOBOO

- Hubei, China (Mainland

- 1-20 sets lead time:25days ; 21-50 sets lead tim30days ; >50sets:to be negotiated

- 100 Set/Sets per Month gantry crane price

Customizable Gantry Crane Solutions for Warehouses, Ports, and Assembly Lines

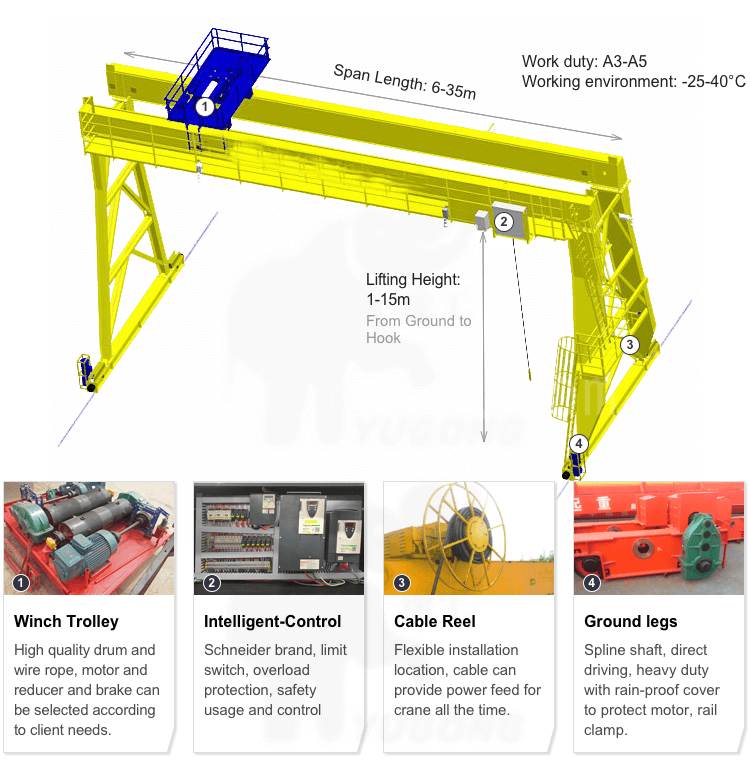

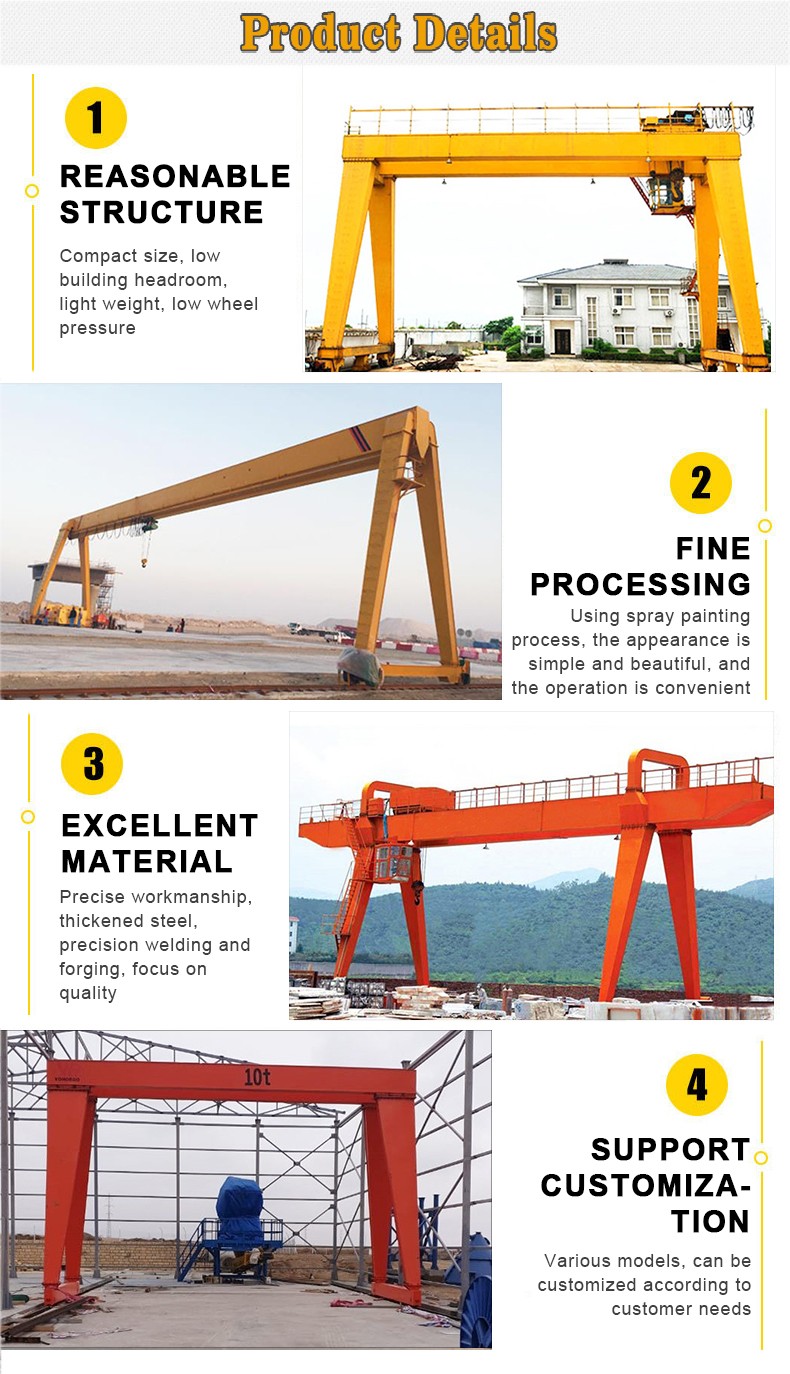

Our gantry cranes offer custom engineering and manufacturing to meet the specific requirements of your facility, project, or industry. From light-duty portable gantry cranes (500kg–5 tons) to rail-mounted container gantry cranes (up to 200 tons), each crane is designed with durability, efficiency, and safety in mind. Structural configurations such as semi-gantry (one side supported by building structure) and full gantry (two-leg support) are available depending on site conditions.

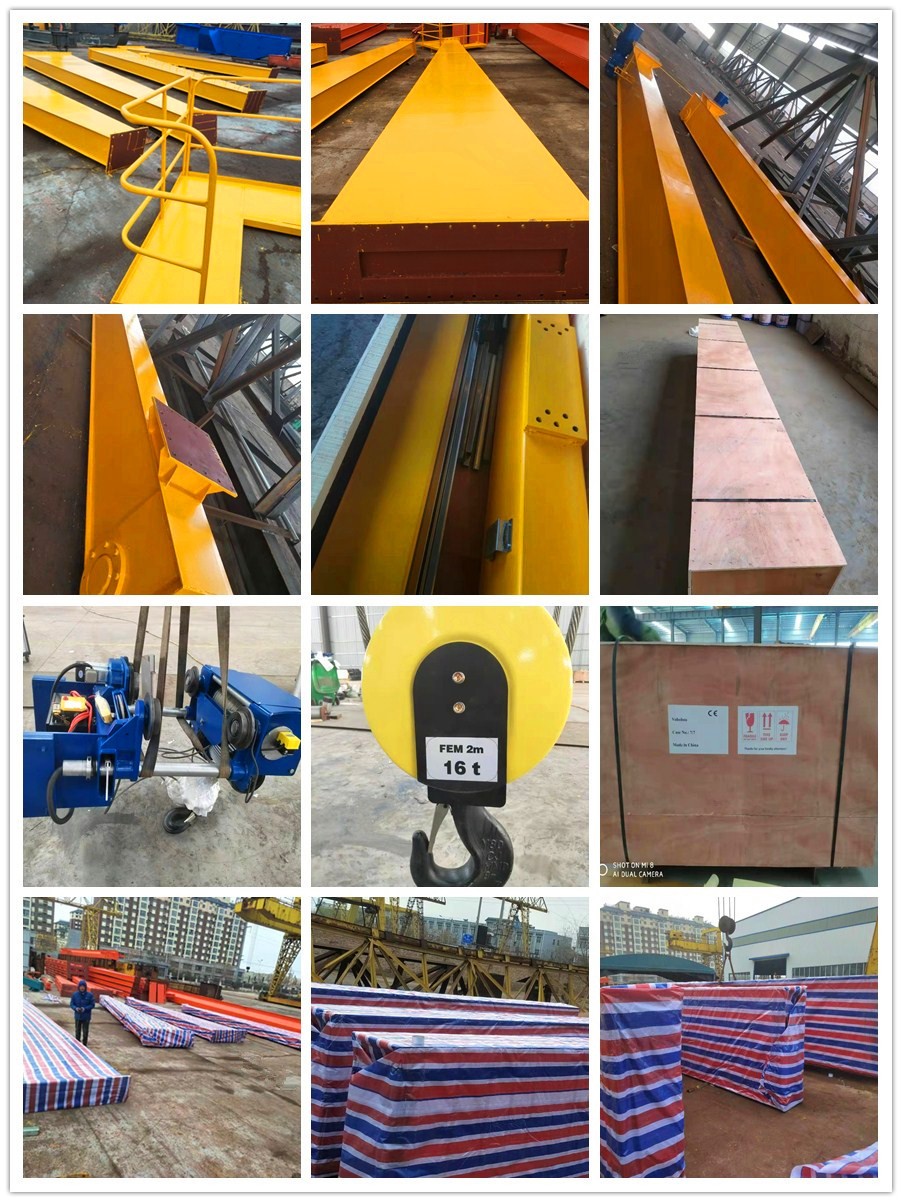

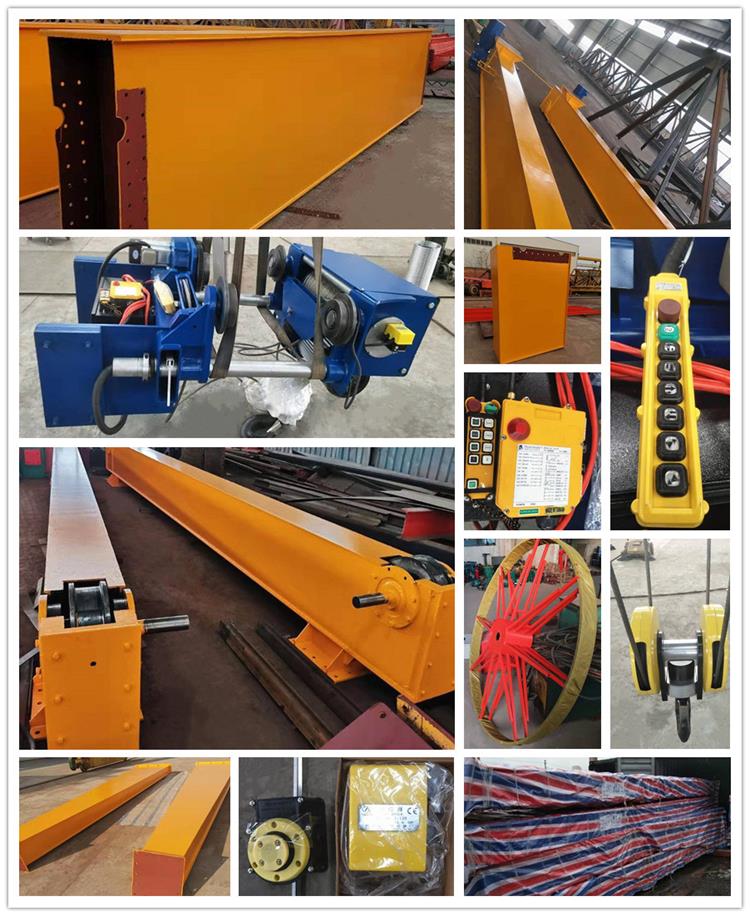

A gantry crane typically consists of a main beam (girder), end carriages or wheels, support legs, lifting hoist, control panels, and electrical wiring systems. Advanced models come equipped with variable frequency drives (VFDs) for smooth start/stop, limit switches, crane interlocks, and motorized end trucks. Our outdoor gantry cranes also feature weatherproof components, corrosion-resistant coatings, and sealed motors to withstand extreme environments.

These cranes are perfect for material transportation between production zones, assembling large equipment, or loading/unloading goods from trucks or containers. Whether you need a gantry crane for modular manufacturing, steel plate handling, or logistics yard operations, we provide highly efficient solutions that can be integrated seamlessly into your workflow.

Product Description:

Customizable Gantry Crane Solutions for Warehouses, Ports, and Assembly Lines

Our gantry cranes offer custom engineering and manufacturing to meet the specific requirements of your facility, project, or industry. From light-duty portable gantry cranes (500kg–5 tons) to rail-mounted container gantry cranes (up to 200 tons), each crane is designed with durability, efficiency, and safety in mind. Structural configurations such as semi-gantry (one side supported by building structure) and full gantry (two-leg support) are available depending on site conditions.

A gantry crane typically consists of a main beam (girder), end carriages or wheels, support legs, lifting hoist, control panels, and electrical wiring systems. Advanced models come equipped with variable frequency drives (VFDs) for smooth start/stop, limit switches, crane interlocks, and motorized end trucks. Our outdoor gantry cranes also feature weatherproof components, corrosion-resistant coatings, and sealed motors to withstand extreme environments.

These cranes are perfect for material transportation between production zones, assembling large equipment, or loading/unloading goods from trucks or containers. Whether you need a gantry crane for modular manufacturing, steel plate handling, or logistics yard operations, we provide highly efficient solutions that can be integrated seamlessly into your workflow.

Single girder gantry crane Specification:

Lifting capacity is 5ton to 32ton;

Span is 12m to 30m;

Lifting height is 6m, 9m, 12m, etc;

Working duty is A5;

Working temperature is -20°C to + 50°C.

Loading capacity | 5 ~ 500t |

Lifting height | 3 ~ 30 m or customized |

Lifting speed | Vary with lifting capacity, or customized. |

Span | 10.5~31.5 m/min |

Lifting mechanism | Wire rope hoist or electric chain hoist |

Working class | A5-A8 |

Working temperature | -20~40 |

Power supply | AC-3Phase-220//230380/400/415/440V-50/60Hz |

Control voltage | DC -36 / 48V |

Motor protection class | IP54 IP55 IP65 |

Control way | Cabin, wireless remote, pendant push button |

Safety device | Buffer,current overload protection,overload device |

Application area | Factory,workshop,warehouse,power station, |

3. Product Application:

Gantry cranes are widely used in various industrial environments where overhead lifting is required but building support structures are not feasible. These cranes are ideal for outdoor yards, construction sites, shipyards, manufacturing workshops, logistics terminals, and steel fabrication plants. They are commonly applied for loading and unloading heavy materials, transporting large components, and assembling prefabricated structures.

Available in single girder, double girder, rail-mounted, and rubber-tyred configurations, gantry cranes offer flexible solutions for both stationary and mobile operations. Their ability to span wide areas without permanent foundation makes them particularly suitable for temporary work zones and open-air operations, delivering efficient, safe, and cost-effective lifting performance.

4. Packing & Shipping