Full Gantry Crane with Rail Mounted Design

- VOHOBOO

- Hubei, China (Mainland

- 1-20 sets lead time:25days ; 21-50 sets lead tim30days ; >50sets:to be negotiated

- 100 Set/Sets per Month gantry crane price

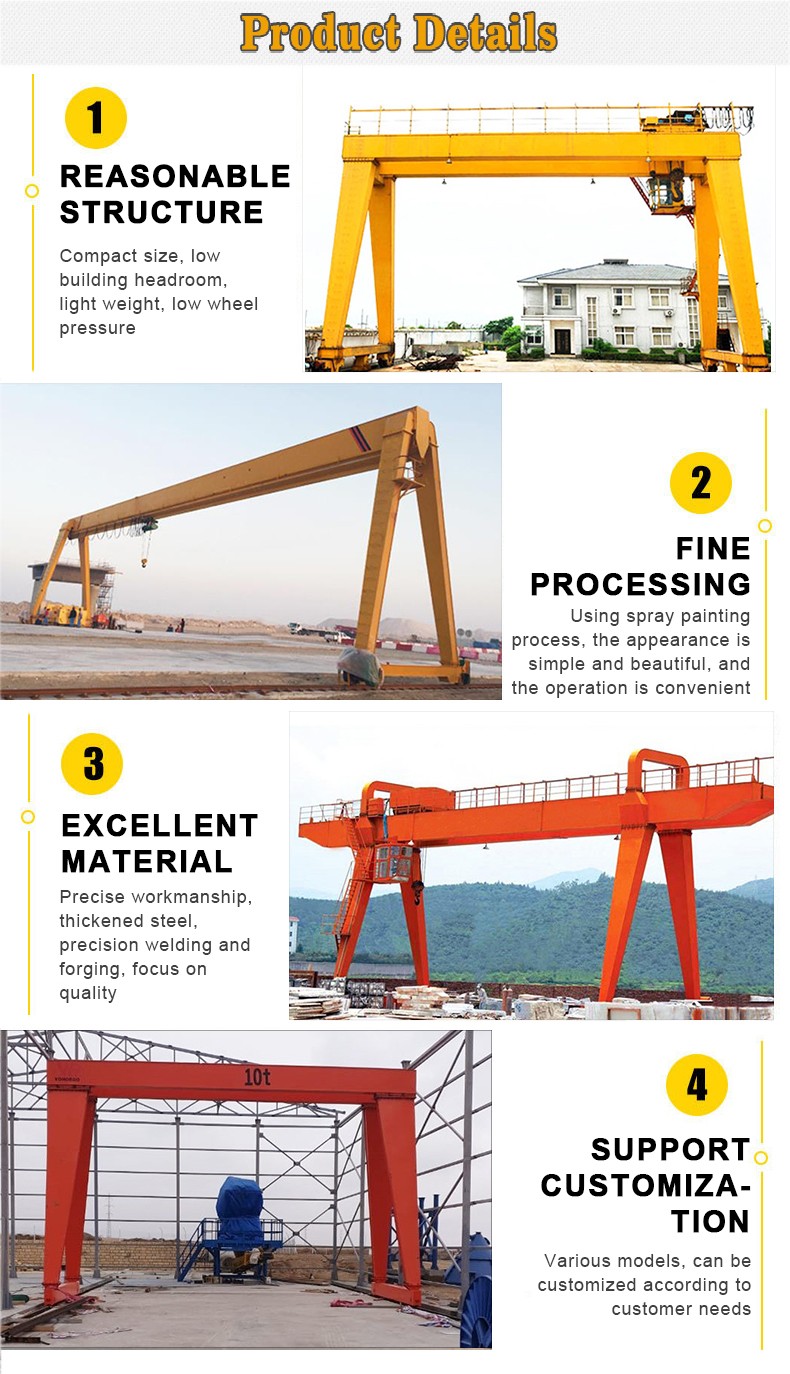

High-Capacity Gantry Cranes Built for Heavy-Duty Lifting Across Industrial Environments

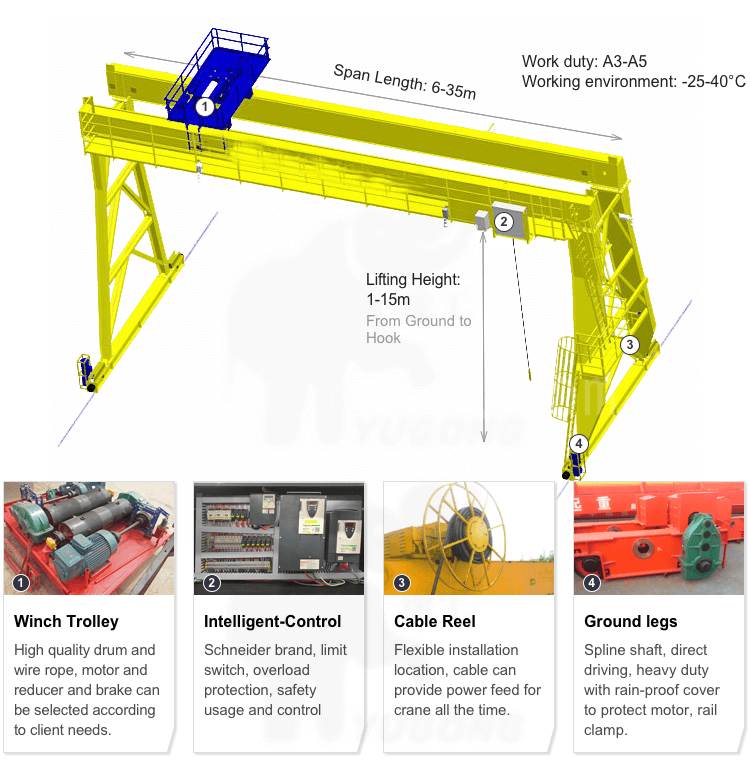

Gantry cranes are heavy-duty lifting systems designed to handle large and bulky loads in open or semi-open areas such as shipyards, construction sites, steel fabrication yards, and logistics terminals. These cranes operate by supporting the load with a horizontal beam (girder) mounted on vertical legs that ride along rails or wheels. With load capacities ranging from 1 ton to over 100 tons, they offer a versatile lifting solution for operations where overhead crane structures are impractical or unavailable.

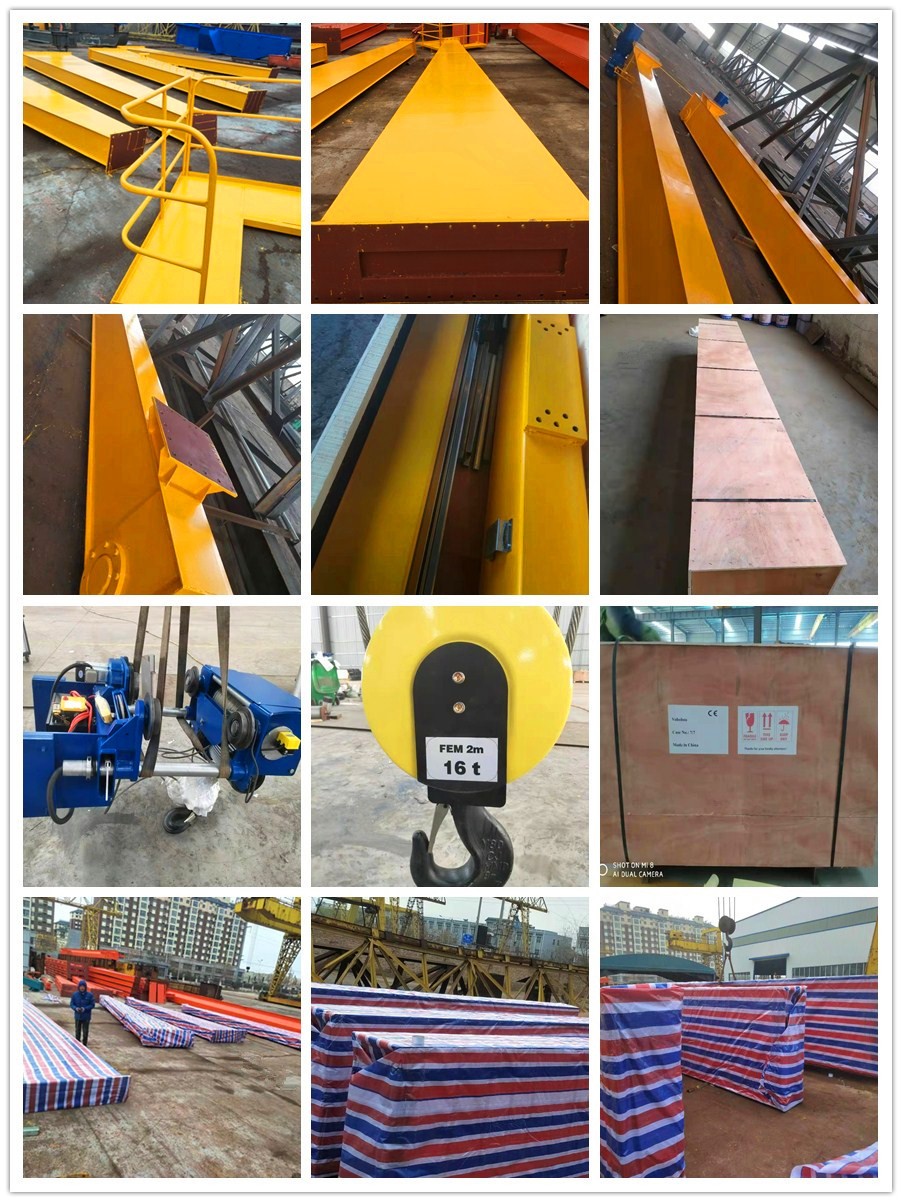

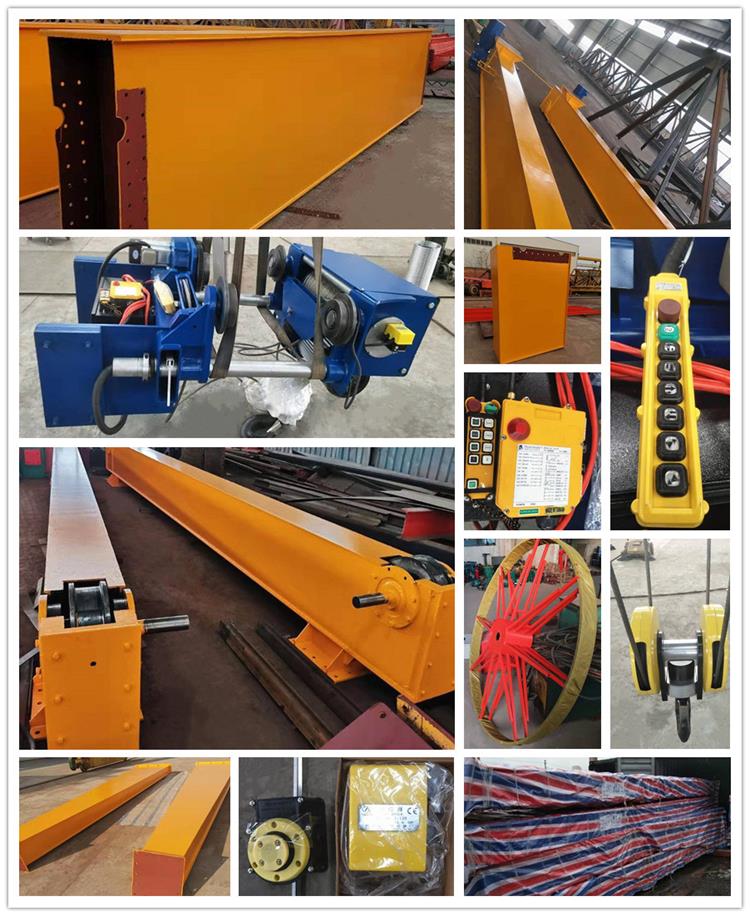

Modern gantry cranes can be configured as single girder or double girder, depending on the application’s required lifting height and load weight. Key components typically include motorized or manual hoists, electrical control cabinets, frequency converters, overload protection systems, limit switches, and travel drives. Optional features such as anti-collision sensors, wireless remote controls, and automated PLC systems greatly enhance safety and efficiency.

Due to their adaptability and high lifting power, gantry cranes are ideal for handling shipping containers, precast concrete segments, large metal coils, wind turbine components, and heavy machinery parts. Their robust steel structure, precision fabrication, and ability to operate in both indoor and outdoor environments make them indispensable to industries where productivity and safety are paramount.

Product Description:

High-Capacity Gantry Cranes Built for Heavy-Duty Lifting Across Industrial Environments

Gantry cranes are heavy-duty lifting systems designed to handle large and bulky loads in open or semi-open areas such as shipyards, construction sites, steel fabrication yards, and logistics terminals. These cranes operate by supporting the load with a horizontal beam (girder) mounted on vertical legs that ride along rails or wheels. With load capacities ranging from 1 ton to over 100 tons, they offer a versatile lifting solution for operations where overhead crane structures are impractical or unavailable.

Modern gantry cranes can be configured as single girder or double girder, depending on the application’s required lifting height and load weight. Key components typically include motorized or manual hoists, electrical control cabinets, frequency converters, overload protection systems, limit switches, and travel drives. Optional features such as anti-collision sensors, wireless remote controls, and automated PLC systems greatly enhance safety and efficiency.

Due to their adaptability and high lifting power, gantry cranes are ideal for handling shipping containers, precast concrete segments, large metal coils, wind turbine components, and heavy machinery parts. Their robust steel structure, precision fabrication, and ability to operate in both indoor and outdoor environments make them indispensable to industries where productivity and safety are paramount.

Single girder gantry crane Specification:

Lifting capacity is 5ton to 32ton;

Span is 12m to 30m;

Lifting height is 6m, 9m, 12m, etc;

Working duty is A5;

Working temperature is -20°C to + 50°C.

Loading capacity | 5 ~ 500t |

Lifting height | 3 ~ 30 m or customized |

Lifting speed | Vary with lifting capacity, or customized. |

Span | 10.5~31.5 m/min |

Lifting mechanism | Wire rope hoist or electric chain hoist |

Working class | A5-A8 |

Working temperature | -20~40 |

Power supply | AC-3Phase-220//230380/400/415/440V-50/60Hz |

Control voltage | DC -36 / 48V |

Motor protection class | IP54 IP55 IP65 |

Control way | Cabin, wireless remote, pendant push button |

Safety device | Buffer,current overload protection,overload device |

Application area | Factory,workshop,warehouse,power station, |

3. Product Application:

Gantry cranes are widely used in various industrial environments where overhead lifting is required but building support structures are not feasible. These cranes are ideal for outdoor yards, construction sites, shipyards, manufacturing workshops, logistics terminals, and steel fabrication plants. They are commonly applied for loading and unloading heavy materials, transporting large components, and assembling prefabricated structures.

Available in single girder, double girder, rail-mounted, and rubber-tyred configurations, gantry cranes offer flexible solutions for both stationary and mobile operations. Their ability to span wide areas without permanent foundation makes them particularly suitable for temporary work zones and open-air operations, delivering efficient, safe, and cost-effective lifting performance.

4. Packing & Shipping