Comprehensive Guide to Jib Cranes: Types, Features, and Advantages

Comprehensive Guide to Jib Cranes: Types, Features, and Advantages

In today’s industrial landscape, jib cranes have become one of the most flexible and efficient lifting solutions available. Compact, versatile, and easy to install, they are ideal for localized material handling in workshops, production lines, warehouses, and maintenance areas. Unlike large-scale bridge or gantry cranes, a jib crane offers precision lifting for smaller work zones, significantly improving productivity and safety.

This guide introduces the main types of jib cranes, their key advantages, and how to select the best model for your application.

1. What Is a Jib Crane?

A jib crane is a type of lifting equipment that features a horizontal arm (jib or boom) mounted to a vertical support structure. The arm supports a hoist, which travels along its length to lift and move materials within a circular working area. The jib can rotate manually or be motorized, depending on the design and capacity requirements.

Main Components:

- Jib Arm / Boom – The main horizontal structure that supports the hoist.

- Column or Wall Mount – The vertical support, which can be floor-mounted or attached to a building wall.

- Hoist and Trolley – The lifting mechanism that travels along the jib arm.

- Rotation Mechanism – Allows the arm to rotate from 180° to 360°.

- Control System – Manual, pendant control, or remote control depending on configuration.

Jib cranes can use electric chain hoists or wire rope hoists for lifting operations, depending on the load type and working environment.

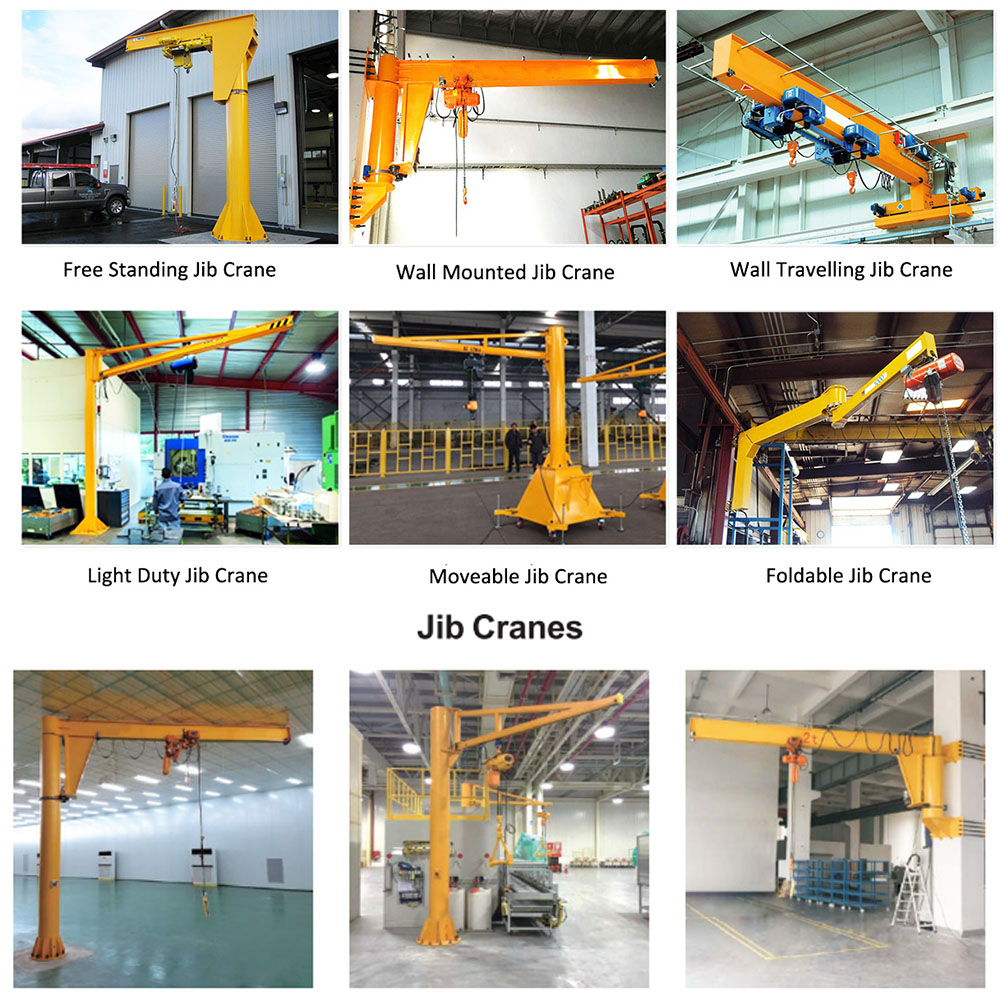

2. Main Types of Jib Cranes

(1) Free-Standing Jib Crane (Pillar Jib Crane)

This is the most common type of jib crane. It is mounted on a reinforced concrete foundation and can rotate a full 360°, providing wide coverage for handling loads in open workspaces.

Advantages:

- Self-supporting structure (no building support required).

- High lifting capacity, typically 0.5 to 10 tons.

- Optional manual or electric slewing.

Applications: Machining workshops, assembly lines, heavy maintenance stations, and loading bays.

(2) Wall-Mounted Jib Crane

The wall-mounted jib crane is attached directly to a wall or vertical column of a building. It is space-saving and economical, making it perfect for areas where floor space is limited.

Advantages:

- Rotation range of 180° or 270°.

- No foundation required.

- Compact structure, easy installation.

Applications: Small workshops, maintenance stations, and assembly cells.

(3) Wall-Traveling Jib Crane

This design combines the flexibility of a jib crane with the mobility of a rail system. It runs along a track mounted on a wall or building column, providing linear movement along a work area.

Advantages:

- Travels along rails for extended coverage.

- Combines horizontal and rotational motion.

Applications: Production lines, mechanical workshops, and storage areas that require frequent load transfers.

(4) Articulating Jib Crane

An articulating jib crane has a two-section arm connected by a pivot point, allowing it to reach around obstacles and into tight spaces where straight-arm cranes cannot operate.

Advantages:

- Extremely flexible movement.

- Can maneuver around corners or machinery.

Applications: Assembly lines, packaging stations, machine loading, and ergonomic work cells.

3. Key Advantages of Jib Cranes

- Compact and Space-Saving Design: Ideal for areas with limited space.

- Easy Installation and Maintenance: Requires minimal installation and service.

- Cost-Effective: Lower purchase and operational costs than large cranes.

- Versatile Configurations: Multiple designs for various applications.

- Enhanced Safety and Precision: Smooth, safe, and accurate lifting.

- Increased Productivity: Reduces manual handling and improves efficiency.

- Customizable Options: Manual or electric rotation, adjustable arm lengths, variable capacities.

4. Typical Industrial Applications

- Manufacturing Workshops

- Assembly and Maintenance Areas

- Automotive Industry

- Warehouses and Logistics

- Shipyards and Marine Applications

5. How to Select the Right Jib Crane

Consider the following factors:

- Lifting Capacity: Determine the maximum weight of your loads.

- Jib Arm Length: Defines the crane’s working radius.

- Rotation Angle: Select 180°, 270°, or 360° based on workspace.

- Mounting Type: Free-standing or wall-mounted depending on structure.

- Operating Environment: Indoor, outdoor, hazardous, or corrosive.

- Hoist Type: Electric chain hoist or wire rope hoist.

- Power and Control: Manual, electric, or remote operation.

6. Conclusion

The jib crane is a reliable, efficient, and customizable lifting solution for modern industry. Whether you need a compact wall-mounted unit for small workstations or a robust pillar jib crane for heavy-duty lifting, the right configuration can significantly enhance your material handling efficiency and safety.