Comprehensive Guide to Overhead Cranes (Bridge Cranes): Types, Structure, and Industrial Applications

Comprehensive Guide to Overhead Cranes (Bridge Cranes): Types, Structure, and Industrial Applications

In modern manufacturing and material handling industries, overhead cranes—also known as bridge cranes—play a vital role in improving productivity, ensuring workplace safety, and reducing manual labor. These lifting systems are used in factories, workshops, warehouses, steel plants, shipyards, and many other industrial environments.

This guide provides a complete overview of overhead crane systems, including their main types, key components, and industrial applications, helping you choose the right crane for your specific needs.

1. What Is an Overhead Crane?

An overhead crane (also known as an EOT crane, short for Electric Overhead Traveling Crane) is a type of material handling equipment used to lift and move heavy loads horizontally within a fixed area.

It typically consists of:

- Bridge (Girder): The main horizontal beam that supports the trolley and hoist.

- End Trucks: Located on both ends of the bridge to allow movement along the runway.

- Hoist and Trolley: The lifting mechanism that moves across the bridge and raises or lowers the load.

- Runway System: Rails installed along the building structure that guide the crane’s movement.

- Control System: Operated by pendant control, wireless remote, or cabin control.

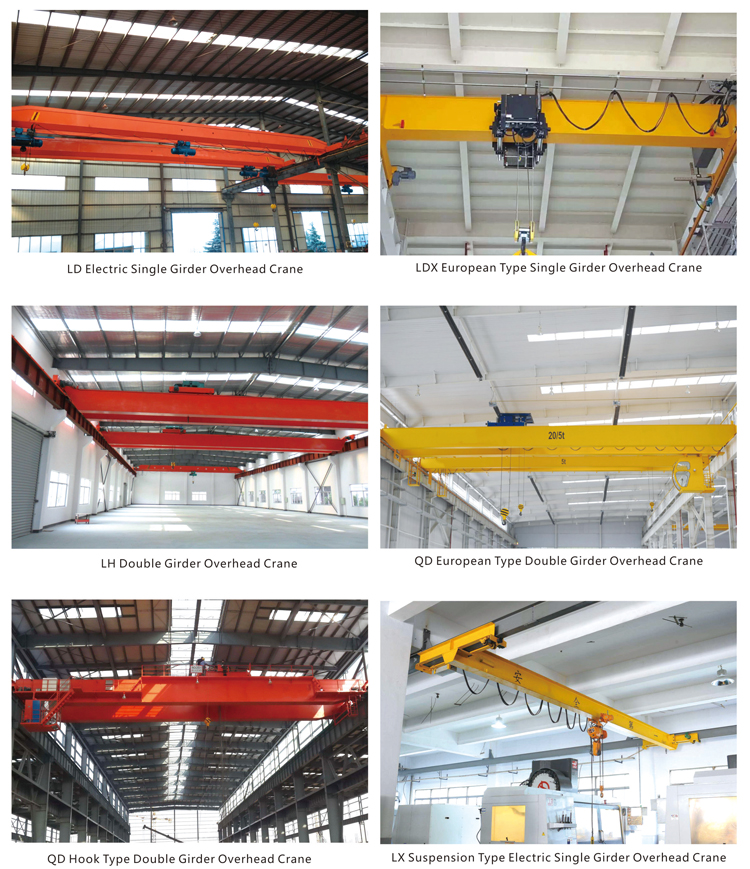

2. Main Types of Overhead Cranes

(1) Single Girder Overhead Crane

Lightweight and cost-effective, suitable for medium-duty lifting. Common in workshops and small warehouses.

(2) Double Girder Overhead Crane

Heavy-duty design for continuous operation, suitable for steel mills and large manufacturing facilities.

(3) Top Running Overhead Crane

Travels on rails mounted on the top of the runway beams, providing maximum lifting height.

(4) Under Running (Underslung) Overhead Crane

Moves along the bottom flange of the runway beam, ideal for low headroom buildings.

(5) Explosion-Proof Overhead Crane

Used in hazardous environments such as oil refineries and chemical plants.

(6) Magnet and Grab Overhead Cranes

Magnetic cranes handle steel plates or scrap metal, while grab cranes lift bulk materials.

3. Key Components of an Overhead Crane

1. Electric Hoist – wire rope or chain type.

2. Trolley Mechanism – moves along the bridge.

3. Runway System – guides longitudinal motion.

4. Electrical Control System – ensures safe operation.

5. Hook or Lifting Attachment – varies by load type.

4. Industrial Applications

Used in manufacturing, steel and metallurgy, automotive, shipbuilding, power generation, warehousing, logistics, and construction.

5. Advantages

- High efficiency and safety

- Reduced labor costs

- Space-saving structure

- Precise control

- Customizable design

- Durable and reliable

6. Choosing the Right Overhead Crane

Consider lifting capacity, span, working environment, duty class, installation type, and control mode. Work with a reliable crane manufacturer for optimal performance and international compliance.

7. Conclusion

Overhead cranes are essential for modern material handling operations. From single girder to double girder systems, choosing the right type improves efficiency, safety, and cost-effectiveness.