Bridge Cranes vs. Jib Cranes: Key Differences, Features, and Applications

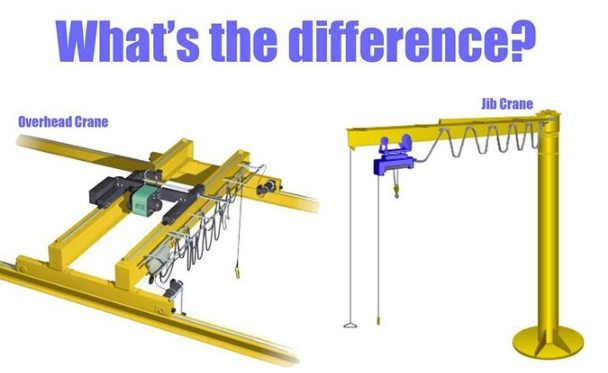

In industrial lifting and material handling, both bridge cranes and jib cranes are widely used to lift and move heavy loads. While they may appear similar at first glance, they serve distinct purposes and are designed for different applications. Understanding the differences between these two types of cranes is essential for selecting the most suitable lifting solution for your factory, warehouse, or workshop.

This article provides a comprehensive overview of bridge cranes and jib cranes, highlighting their key differences, features, advantages, and industrial applications.

1. What Is a Bridge Crane?

A bridge crane, also known as an overhead crane, consists of a bridge spanning two parallel runways, a hoist mounted on the bridge, and the ability to move the load both horizontally and vertically. Bridge cranes are commonly used in heavy-duty industrial environments where large loads need to be transported over long spans.

Key Features of Bridge Cranes:

- Covers a large working area with full horizontal and vertical movement.

- Can handle medium to heavy loads, from a few tons up to hundreds of tons.

- Available in single girder and double girder configurations.

- Equipped with electric hoists, trolleys, and bridge travel mechanisms.

- Designed for indoor or outdoor use, depending on the runway and support structure.

Applications of Bridge Cranes:

- Steel plants, foundries, and shipyards.

- Large-scale manufacturing workshops.

- Warehouses with heavy material handling.

- Assembly lines requiring precise and repetitive lifting.

2. What Is a Jib Crane?

A jib crane is a smaller, localized lifting system that consists of a horizontal arm (jib or boom) mounted to a vertical column or wall, with a hoist that moves along the arm. Jib cranes are ideal for workstations, production cells, or maintenance areas, where a limited lifting radius is sufficient.

Key Features of Jib Cranes:

- Provides lifting within a circular working radius (usually 180° to 360° rotation).

- Supports light to medium loads, typically up to 10 tons.

- Available in free-standing (pillar) or wall-mounted configurations.

- Can use manual or electric hoists depending on application.

- Compact, cost-effective, and easy to install in confined spaces.

Applications of Jib Cranes:

- Workstations and machine loading areas.

- Maintenance and repair stations.

- Small warehouses and assembly lines.

- Automotive and aerospace workshops.

3. Key Differences Between Bridge Cranes and Jib Cranes

- Movement: Bridge crane offers full horizontal (bridge travel) + vertical lift; Jib crane has limited horizontal (swinging jib) + vertical lift.

- Load Capacity: Bridge crane handles medium to heavy loads (1–100+ tons); Jib crane handles light to medium loads (0.25–10 tons).

- Working Area: Bridge crane covers large spans; Jib crane covers small localized radius.

- Installation: Bridge crane requires runway beams and structural support; Jib crane is floor-mounted pillar or wall-mounted.

- Flexibility: Bridge crane covers large areas; Jib crane suits confined spaces.

- Cost: Bridge crane has higher investment; Jib crane is more affordable.

- Applications: Bridge crane suits heavy manufacturing and large industrial sites; Jib crane suits workstations and assembly areas.

4. Advantages of Bridge Cranes

- Wide Coverage: Ideal for large workshops and warehouses.

- High Load Capacity: Can lift very heavy and oversized loads.

- Smooth Material Handling: Trolley and bridge travel ensure precise movement.

- Durability: Designed for heavy-duty industrial environments.

- Customizable: Single or double girder, indoor/outdoor, various hoist types.

5. Advantages of Jib Cranes

- Compact and Space-Saving: Perfect for localized lifting without requiring runways.

- Cost-Effective: Lower purchase and installation costs.

- Easy Installation: Wall-mounted or pillar-mounted designs are straightforward.

- Flexible Operation: Electric or manual rotation and hoist options.

- Productivity Improvement: Brings lifting power directly to the workstation.

6. How to Choose Between a Bridge Crane and a Jib Crane

- Load Requirements: Heavy loads favor bridge cranes; lighter loads can use jib cranes.

- Workspace Size: Large areas require bridge cranes; confined workstations suit jib cranes.

- Movement Needs: Full-span horizontal coverage necessitates a bridge crane; limited radius may use a jib crane.

- Budget and Installation: Consider cost, structural support, and long-term maintenance.

- Frequency and Workflow: High-frequency, multi-station lifting favors bridge cranes; localized repetitive tasks are ideal for jib cranes.

7. Conclusion

Both bridge cranes and jib cranes are indispensable tools in modern material handling. Choosing the right type depends on load capacity, working area, installation constraints, and budget.

- Bridge cranes excel in large-scale lifting, heavy-duty operations, and warehouse-wide coverage.

- Jib cranes provide a cost-effective, compact solution for workstations, assembly areas, and localized lifting tasks.

By understanding their differences and capabilities, industrial facilities can optimize lifting efficiency, ensure safety, and enhance productivity.