Slewing Arm Jib Crane

- VOHOBOO

- Hubei, China (Mainland

- 2~4 weeks after your payment

- 2000 Set/Sets per Month gantry crane 1 ton

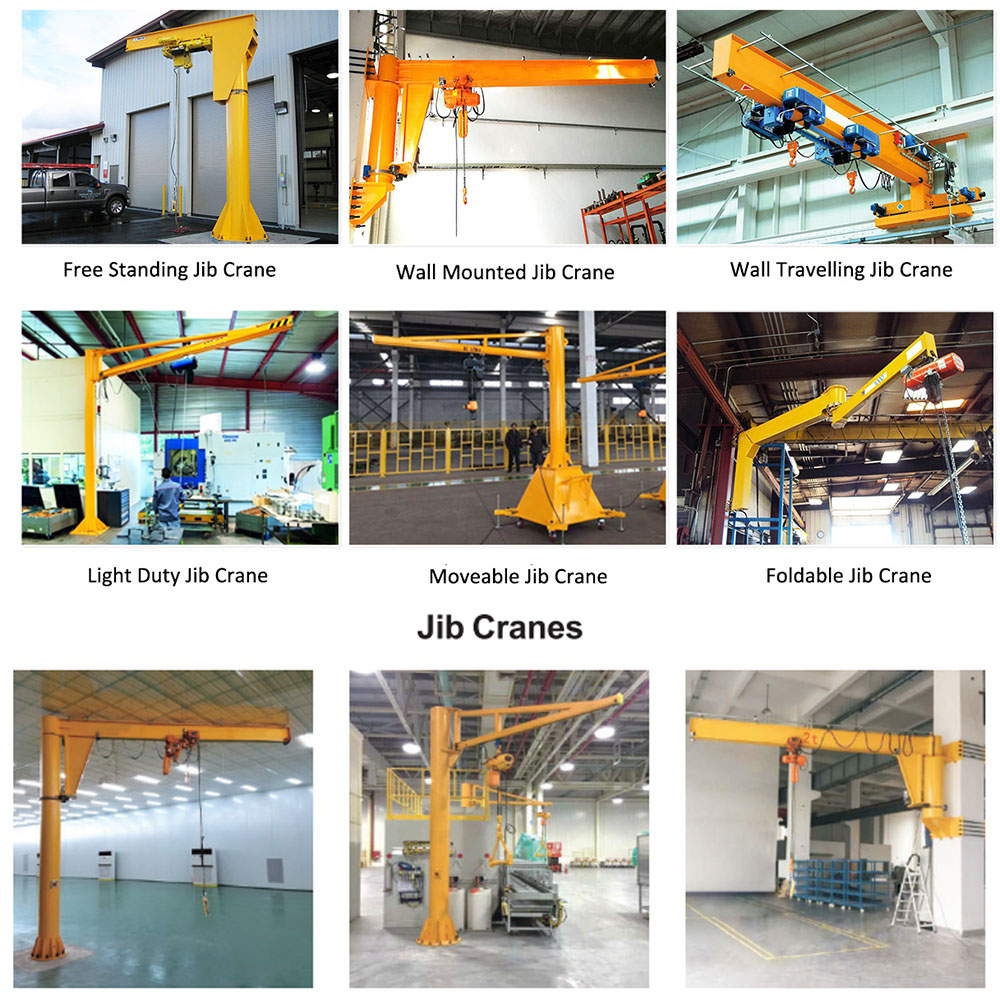

Wall-Travelling Jib Crane for Multi-Station Assembly Lines and Logistics Centers

Designed for applications requiring lateral movement along a building wall or support beam, our wall-travelling jib crane offers an efficient solution for multi-station handling. It travels horizontally on rails while allowing the boom to rotate or remain fixed, covering long workbenches or conveyor lines without occupying valuable floor space. This system is ideal for logistics centers, warehouse picking operations, and automotive component assembly. With a lifting range up to 2 tons, it integrates seamlessly into production flows, minimizing manual labor and improving cycle times.

Versatile Jib Cranes Designed for Precision Lifting and Localized Workstations

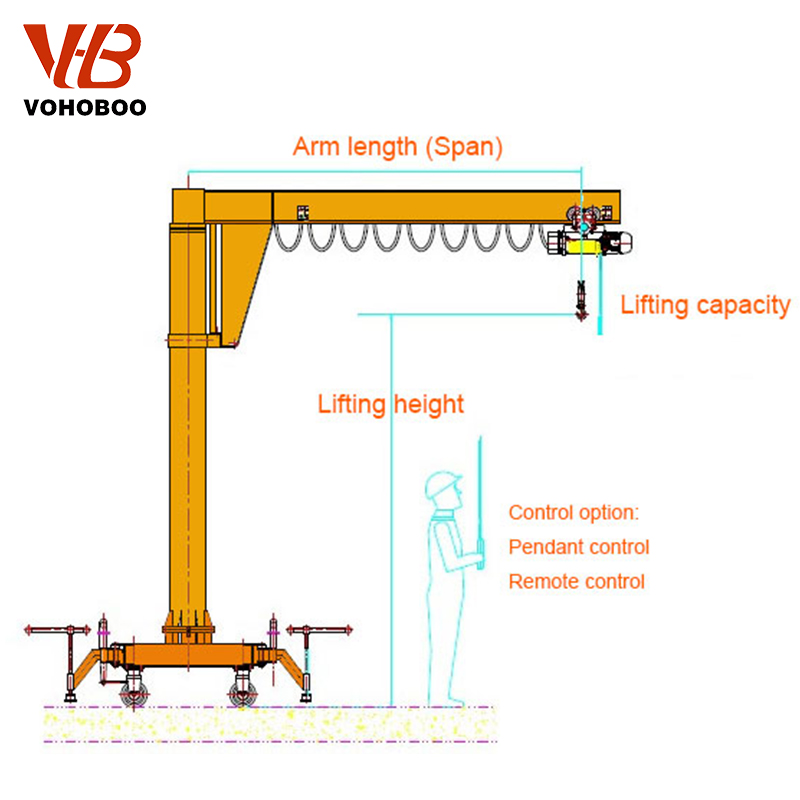

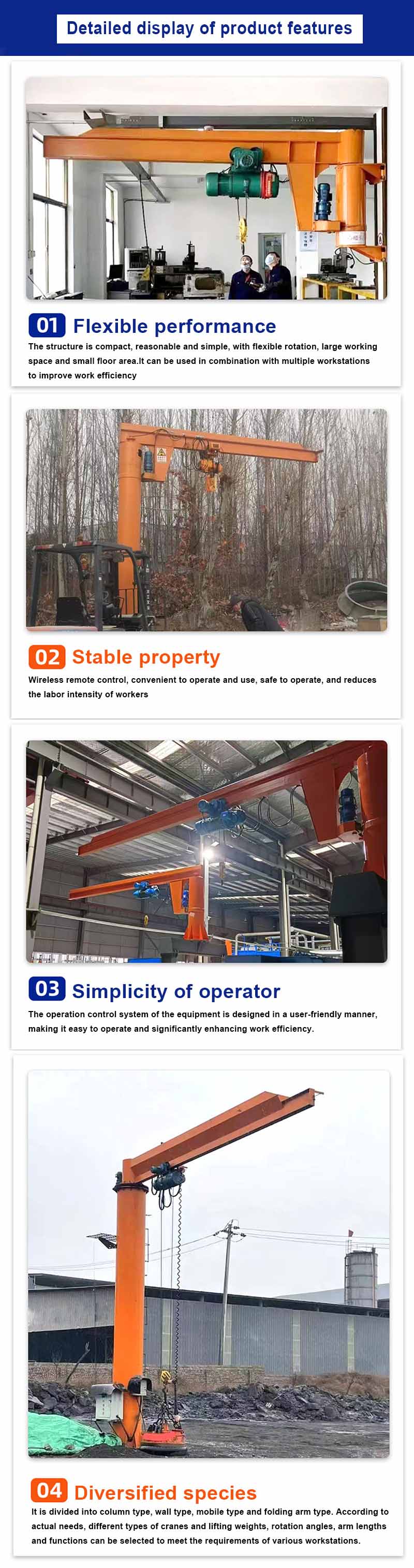

Jib cranes are a critical component in modern material handling systems, providing localized lifting and positioning capabilities within a defined work area. These cranes feature a rotating horizontal arm (jib) mounted on a vertical support column or wall structure, allowing for easy and safe manipulation of loads. Available in various configurations—including pillar-mounted, wall-mounted, and wall-travelling types—they are adaptable to both new and existing workshops with minimal structural modification.

Lifting capacities typically range from 0.125 ton to 5 tons, making jib cranes suitable for everything from light-duty component assembly to heavier part positioning in manufacturing environments. The cranes can be configured with manual or electric slewing, and hoists can be selected based on application needs, such as electric chain hoists, wire rope hoists, or pneumatic hoists for explosion-prone environments. Their design allows for smooth, continuous 180° to 360° rotation, enabling operators to move loads quickly and efficiently between machines, pallets, and workstations.

These cranes are commonly installed in automotive workshops, welding bays, mechanical assembly lines, and tool manufacturing areas, where precision, safety, and operator control are key. The compact footprint and independent operation make jib cranes an excellent choice for decentralized material handling, reducing operator fatigue and increasing production throughput.

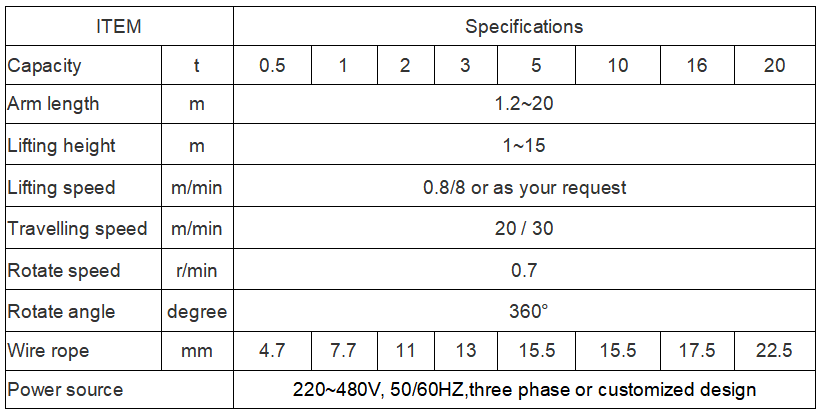

Technical parameter:

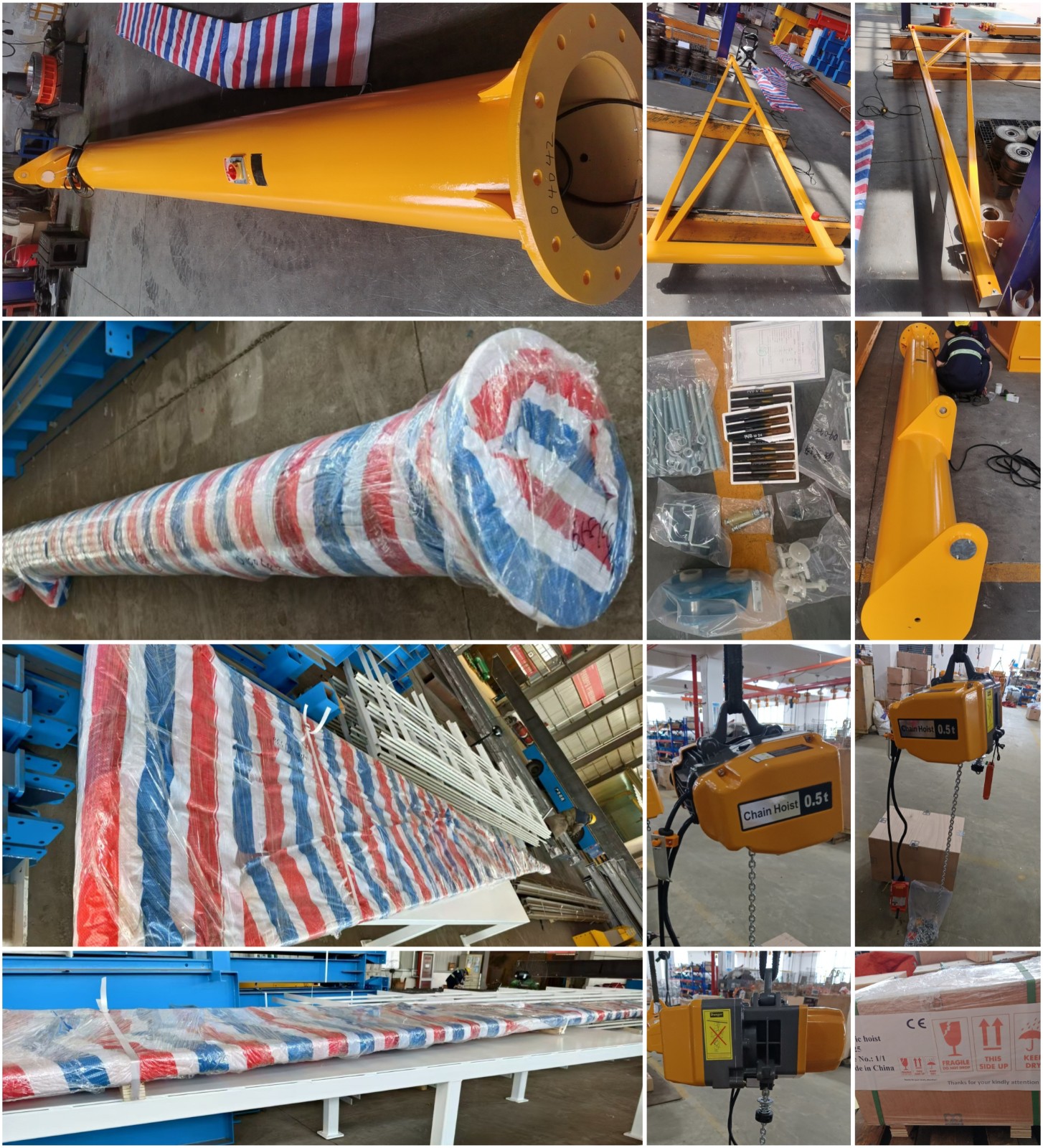

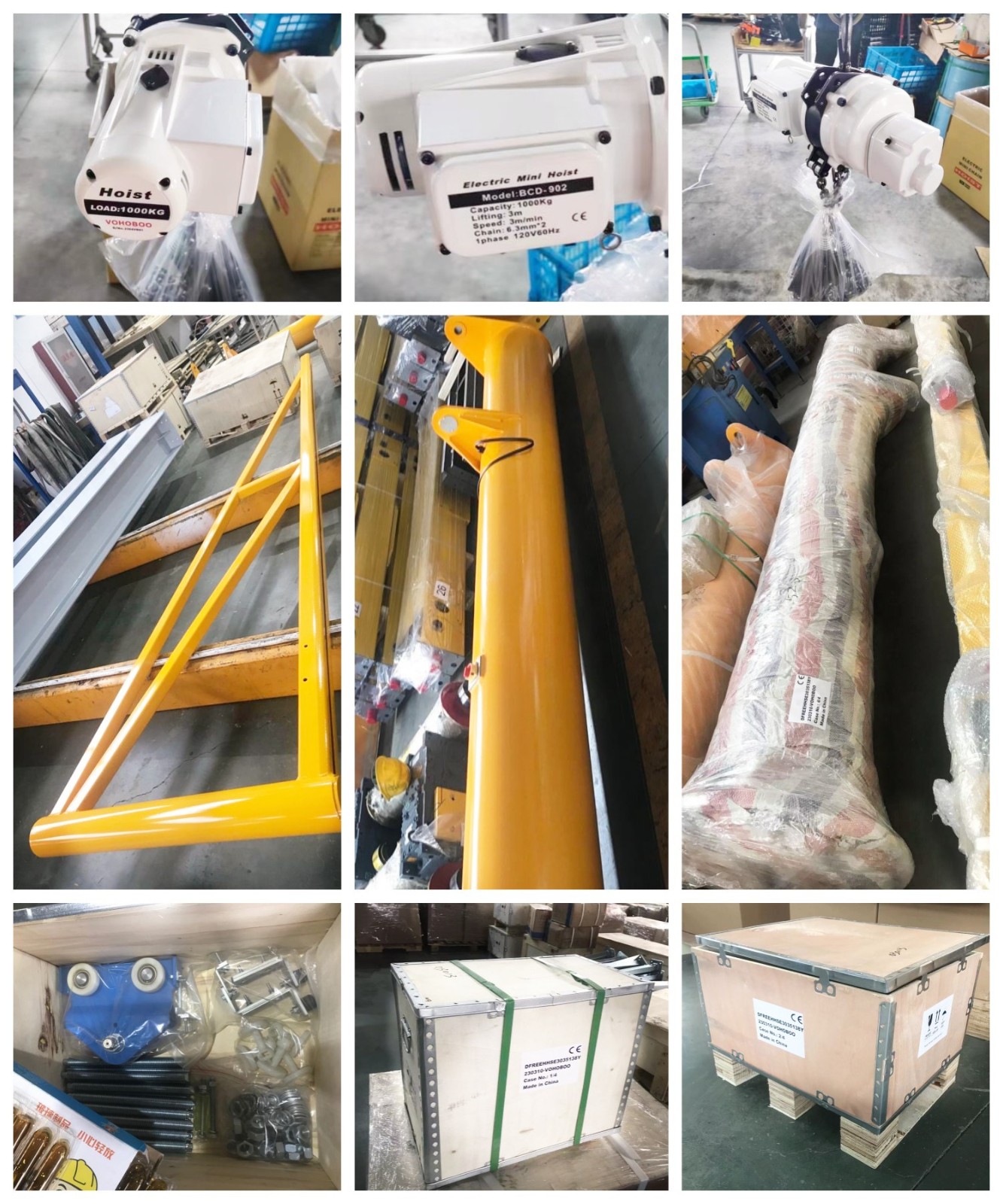

Product Details

Packing&Delivery