Bracket Jib Crane with Electric Hoist

- VOHOBOO

- Hubei, China (Mainland

- 2~4 weeks after your payment

- 2000 Set/Sets per Month gantry crane 1 ton

Structural Design and Technical Specifications

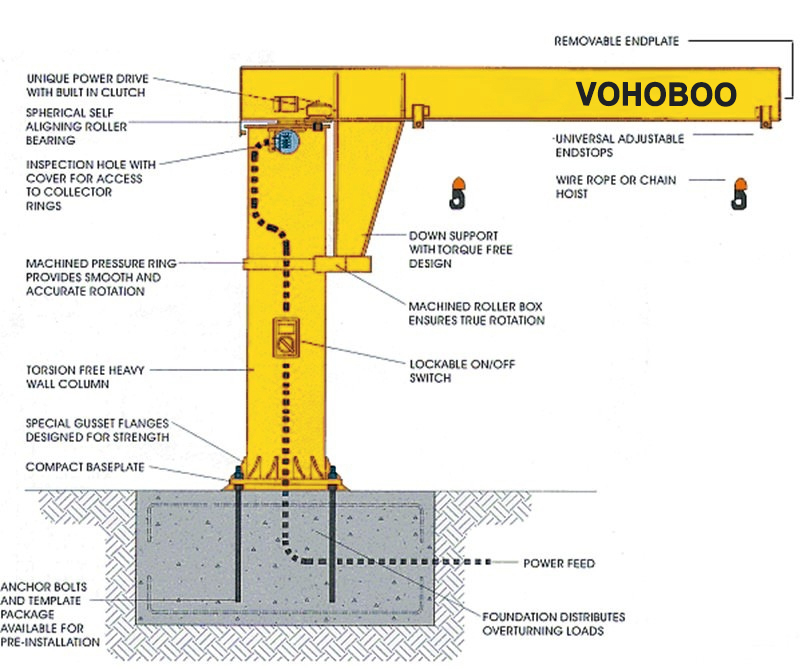

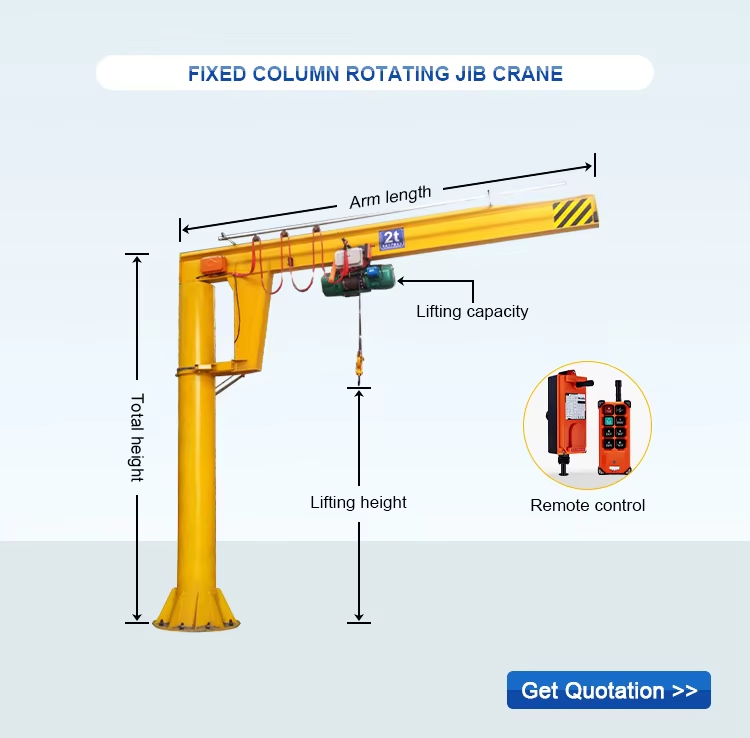

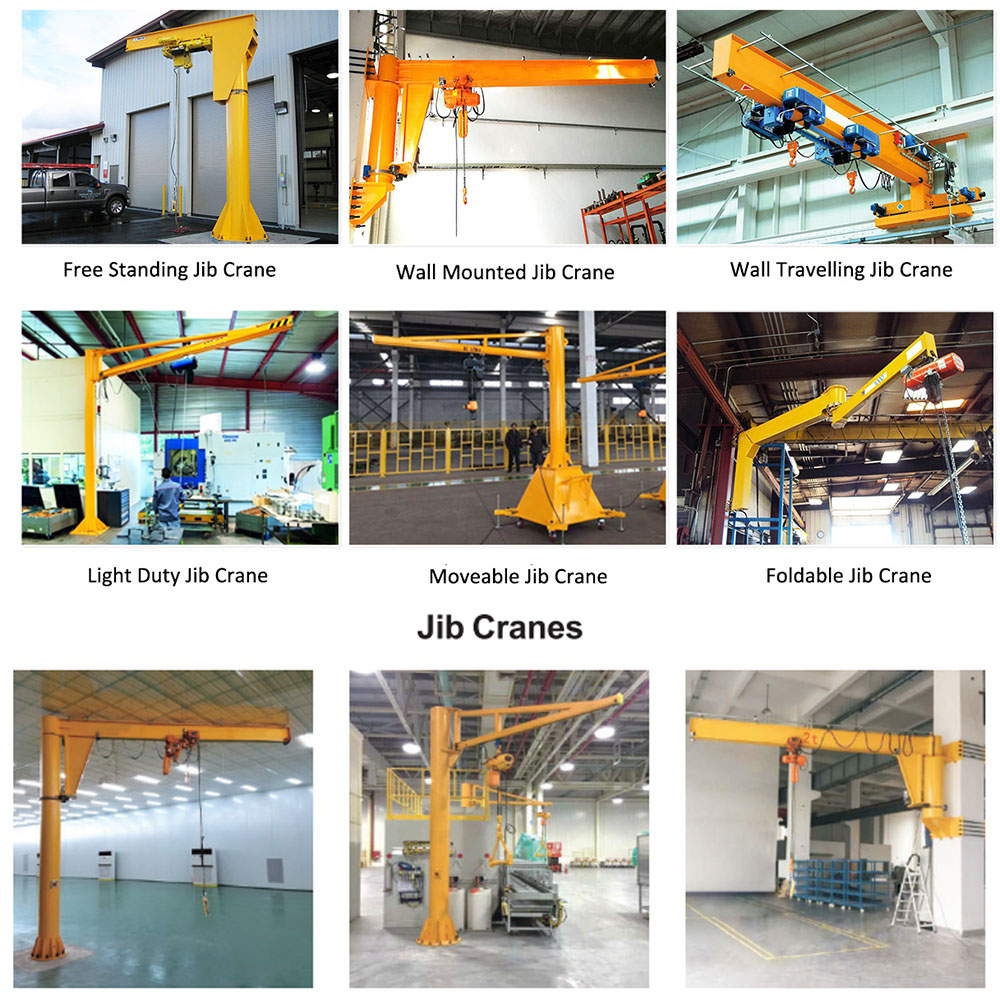

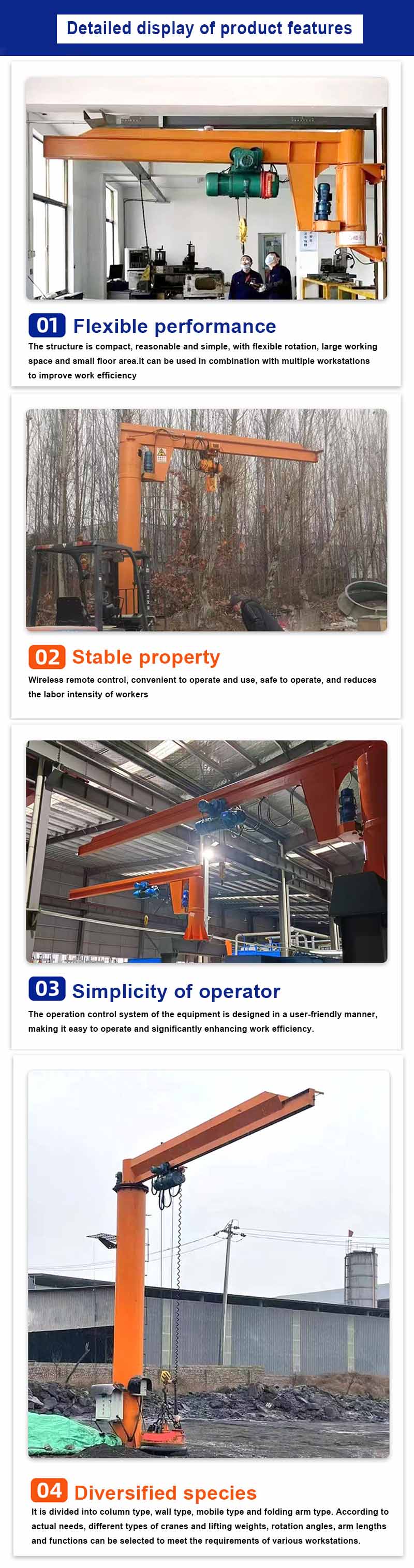

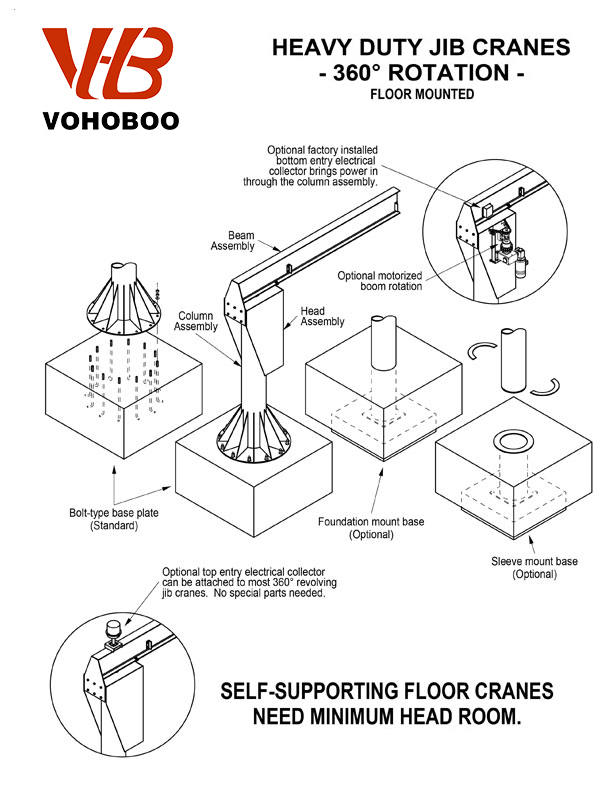

The design of a jib crane is centered around stability, precision, and versatility. The main components include the mast or column, jib arm (boom), slewing mechanism, and lifting unit. The mast is anchored to a foundation or wall to provide structural stability, while the jib arm extends horizontally to support the hoist and trolley. For free-standing types, a reinforced base plate and anchor bolts ensure the crane can safely handle heavy loads without structural deformation.

The slewing mechanism, which allows the jib arm to rotate, can be manually operated for light-duty applications or powered by an electric motor for heavy loads and high-frequency usage. Rotation ranges can be configured from 180° to full 360°, depending on installation space and operational requirements. The hoist unit—whether an electric chain hoist or wire rope hoist—is mounted on a trolley that moves along the jib arm, providing precise horizontal load positioning.

Technical customization options include lifting capacities from 0.125 tons to 20 tons, outreach lengths tailored to workspace dimensions, lifting heights determined by building clearance, and hoist speed adjustments for delicate or heavy-duty handling. Safety features such as overload protection devices, emergency stop functions, limit switches, and anti-sway controls can be integrated to ensure compliance with international safety standards.

The steel structure is engineered to resist bending and torsional forces, with a robust finish to withstand harsh industrial environments. Bearings, gears, and motors are designed for long service life with minimal maintenance, making jib cranes a cost-effective and reliable solution for various material handling tasks.

Structural Design and Technical Specifications

The design of a jib crane is centered around stability, precision, and versatility. The main components include the mast or column, jib arm (boom), slewing mechanism, and lifting unit. The mast is anchored to a foundation or wall to provide structural stability, while the jib arm extends horizontally to support the hoist and trolley. For free-standing types, a reinforced base plate and anchor bolts ensure the crane can safely handle heavy loads without structural deformation.

The slewing mechanism, which allows the jib arm to rotate, can be manually operated for light-duty applications or powered by an electric motor for heavy loads and high-frequency usage. Rotation ranges can be configured from 180° to full 360°, depending on installation space and operational requirements. The hoist unit—whether an electric chain hoist or wire rope hoist—is mounted on a trolley that moves along the jib arm, providing precise horizontal load positioning.

Technical customization options include lifting capacities from 0.125 tons to 20 tons, outreach lengths tailored to workspace dimensions, lifting heights determined by building clearance, and hoist speed adjustments for delicate or heavy-duty handling. Safety features such as overload protection devices, emergency stop functions, limit switches, and anti-sway controls can be integrated to ensure compliance with international safety standards.

The steel structure is engineered to resist bending and torsional forces, with a robust finish to withstand harsh industrial environments. Bearings, gears, and motors are designed for long service life with minimal maintenance, making jib cranes a cost-effective and reliable solution for various material handling tasks.

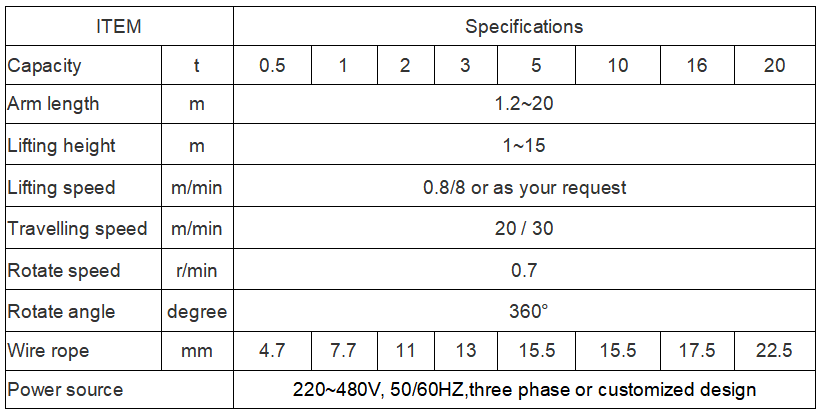

Technical parameter:

Product Details

Packing&Delivery