Heavy Duty Overhead Bridge Crane with Reliable Lifting Motor

- VOHOBOO

- Hubei, China (Mainland

- 2~4 weeks after your payment

- 100 Set/Sets per Month double girder EOT crane

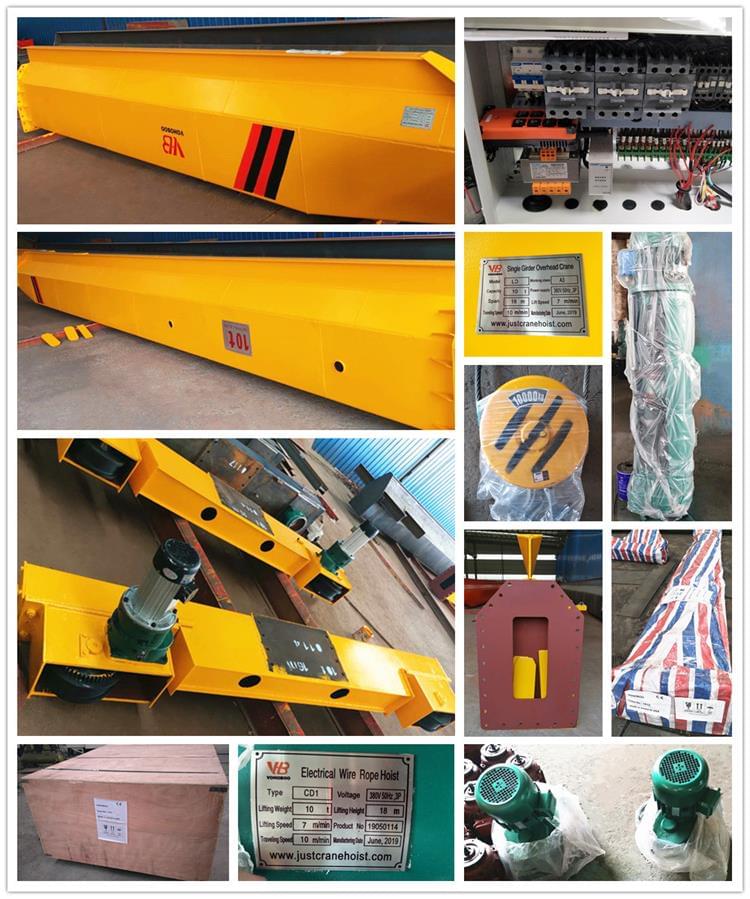

Bridge cranes are designed with a combination of strength, safety, and versatility to handle various industrial lifting tasks. The core structure includes the girder (single or double), end trucks that run along the rails, and a hoist-trolley unit that lifts and moves loads horizontally. Modern cranes are equipped with electric wire rope hoists capable of handling loads from 1 ton up to 200 tons, making them suitable for both light-duty assembly lines and heavy steel fabrication workshops. The control system can be pendant, remote, or cabin-based, depending on operator preference and site conditions. Advanced features such as anti-sway technology, frequency inverter drives, and precise positioning improve accuracy and reduce wear. Applications cover a wide spectrum including manufacturing plants, logistics warehouses, foundries, shipbuilding, and large infrastructure projects. With their modular design, bridge cranes are easy to install, expand, and maintain. The efficiency of overhead cranes lies in their ability to reduce manual handling, optimize workshop workflow, and ensure safe, reliable lifting for demanding industrial environments.

Bridge cranes are designed with a combination of strength, safety, and versatility to handle various industrial lifting tasks. The core structure includes the girder (single or double), end trucks that run along the rails, and a hoist-trolley unit that lifts and moves loads horizontally. Modern cranes are equipped with electric wire rope hoists capable of handling loads from 1 ton up to 200 tons, making them suitable for both light-duty assembly lines and heavy steel fabrication workshops. The control system can be pendant, remote, or cabin-based, depending on operator preference and site conditions. Advanced features such as anti-sway technology, frequency inverter drives, and precise positioning improve accuracy and reduce wear. Applications cover a wide spectrum including manufacturing plants, logistics warehouses, foundries, shipbuilding, and large infrastructure projects. With their modular design, bridge cranes are easy to install, expand, and maintain. The efficiency of overhead cranes lies in their ability to reduce manual handling, optimize workshop workflow, and ensure safe, reliable lifting for demanding industrial environments.