Common Causes of Crane Accidents

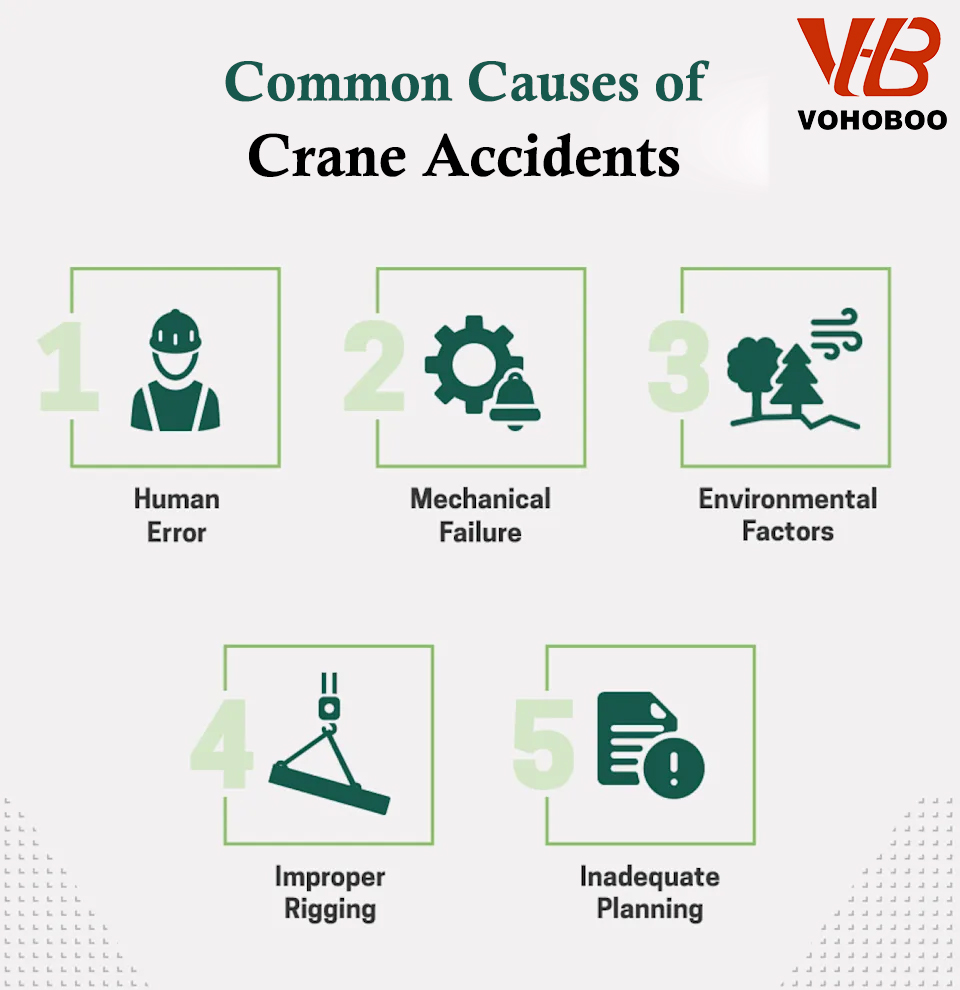

Common Causes of Crane Accidents

Introduction

Cranes are essential in the modern lifting and material handling industry — from construction sites and shipyards to manufacturing plants and logistics centers. However, cranes also represent one of the most potentially dangerous types of industrial machinery when not used properly.

Every year, thousands of crane-related incidents occur worldwide, resulting in serious injuries, property damage, and costly downtime. The majority of these accidents are preventable with proper training, maintenance, and operational control.

1. Operator Error and Inadequate Training

One of the leading causes of crane accidents is operator error, often due to insufficient training or lack of certification.

Prevention Tips:

• Ensure operators are properly licensed and trained according to local safety standards.

• Conduct regular refresher courses and evaluations.

• Emphasize communication protocols between operators and signalers.

2. Overloading the Crane

Every crane has a rated load capacity, and exceeding this limit is one of the most dangerous mistakes in lifting operations.

Prevention Tips:

• Always check the load chart before each lift.

• Use load indicators or limit switches.

• Educate operators about dynamic loading effects such as wind and motion.

3. Poor Communication and Coordination

Many crane accidents occur due to miscommunication between the operator and ground personnel.

Prevention Tips:

• Assign a qualified signal person for every lift.

• Use standardized hand signals or wireless headsets.

• Implement radio check protocols before starting operations.

4. Mechanical Failures and Poor Maintenance

Crane components are subject to heavy wear and stress. Neglecting maintenance can lead to part failures.

Prevention Tips:

• Follow the manufacturer’s maintenance schedule strictly.

• Perform daily pre-operation inspections.

• Replace any damaged component immediately.

5. Poor Site Conditions and Ground Instability

Even a perfectly functioning crane can fail if ground conditions are unstable.

Prevention Tips:

• Conduct a site survey before setup.

• Use proper outrigger mats.

• Monitor ground conditions continuously.

6. Environmental Factors (Wind, Weather, and Visibility)

Wind and weather conditions can dramatically affect crane stability and load control.

Prevention Tips:

• Monitor weather forecasts.

• Use anemometers to measure wind speed.

• Ensure adequate lighting for night shifts.

7. Improper Assembly or Setup

Incorrect assembly or dismantling is a major cause of accidents.

Prevention Tips:

• Ensure assembly is done by qualified personnel.

• Follow the manufacturer’s manual.

• Conduct load and function tests before operation.

8. Lack of Regular Inspection and Compliance Audits

Cranes require periodic inspection by certified inspectors to ensure compliance.

Prevention Tips:

• Perform daily, monthly, and annual inspections.

• Keep a logbook of all maintenance.

• Work only with certified inspection agencies.

9. Human Negligence and Complacency

Complacency leads to skipped safety checks and rushed lifts.

Prevention Tips:

• Promote a safety-first culture.

• Reward compliance and safe behavior.

• Enforce strict disciplinary action for violations.

Conclusion

Crane accidents are not random—they result from human error, poor maintenance, or unsafe conditions.

Key Takeaways:

• Train and certify all operators.

• Maintain and inspect cranes regularly.

• Never exceed load limits.

• Communicate effectively.

A well-maintained and properly operated crane is not only safer but also more productive and cost-effective.

SEO Keywords

crane accidents, crane safety, overhead crane hazards, hoist accidents, crane operator training, lifting safety tips, crane maintenance, OSHA crane standards, industrial safety, accident prevention in cranes, crane load limit, crane inspection checklist, crane safety management.