A Complete Guide to Electric Chain Hoist Types: — Differences, Applications, and How to Choose the Right One

A Complete Guide to Electric Chain Hoist Types: Fixed, Manual Trolley, Electric Trolley, and Low-Headroom — Differences, Applications, and How to Choose the Right One

A Complete Guide to Electric Chain Hoist Types: Fixed, Manual Trolley, Electric Trolley, and Low-Headroom — Differences, Applications, and How to Choose the Right One

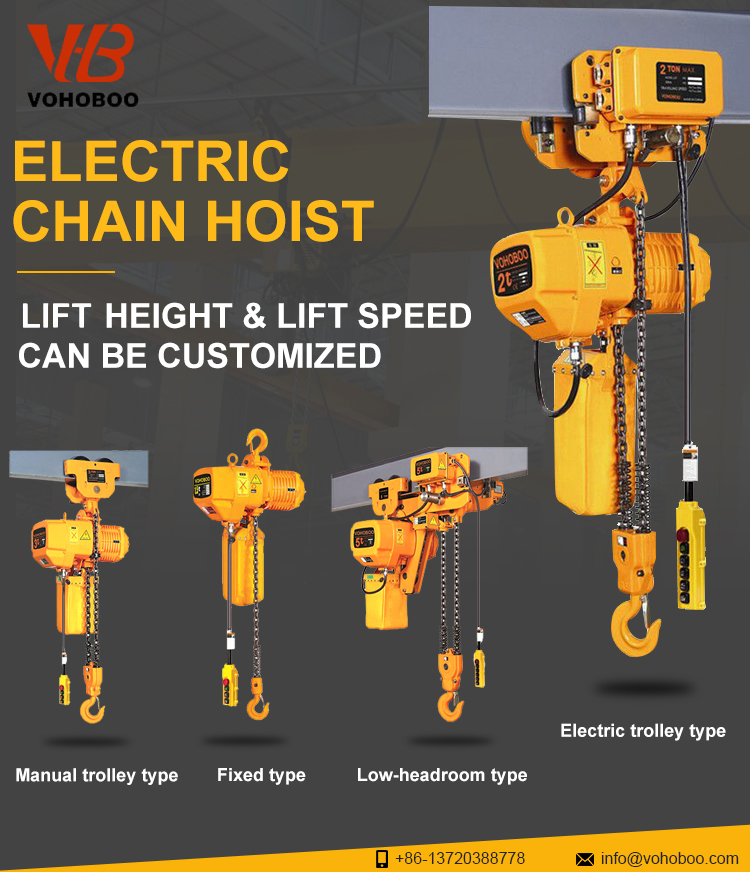

Electric chain hoists are among the most widely used lifting devices in modern industrial environments. Their compact size, reliability, and flexible installation options make them ideal for light to medium-duty material handling. However, electric chain hoists come in several types, each designed to suit different application requirements, building layouts, and movement needs. The most common configurations include:

·Fixed (Stationary) Electric Chain Hoists

·Manual Trolley Electric Chain Hoists

·Electric Trolley Electric Chain Hoists

·Low-Headroom Electric Chain Hoists

Understanding the differences between these types—along with their typical working environments, advantages, and limitations—is essential when selecting the right equipment for your facility.

This comprehensive guide explores each type in detail and explains how to choose the best hoist configuration based on your operation’s lifting height, load capacity, movement requirements, and workspace constraints.

1. Fixed (Stationary) Electric Chain Hoist

A fixed electric chain hoist, also known as a stationary hoist, is mounted in a permanent location without horizontal travel capability. It can be mounted via:

·hook suspension

·lug (eye) suspension

·foot or base mounting

This type is often used for lifting operations requiring only vertical movement.

Key Features

·Simplest structure and easiest installation

·Lowest cost among all electric chain hoist types

·Stable lifting performance

·Minimal maintenance requirements

·Compatible with jib cranes, monorails, or fixed frames

Typical Applications

·Machinery assembly stations

·Equipment maintenance and repair shops

·Workbenches or fixed-position lifting tasks

·Production lines requiring repeated vertical lifting at a single point

Advantages

·Cost-effective and reliable

·Perfect for repetitive vertical lifts

·Minimal installation space needed

Limitations

·No horizontal movement

·Not suitable for production lines requiring load transfer from point to point

Choose this type if your lifting needs are fixed in one location and the load does not require travel along a beam.

2. Manual Trolley Electric Chain Hoist

A manual trolley hoist combines an electric lifting mechanism with a hand-pushed or hand-chain trolley for horizontal travel along an overhead I-beam.

While the lifting is electric and effortless, the horizontal movement is handled manually.

Key Features

·Lower cost than electric trolley models

·Simple structure with minimal maintenance

·Highly flexible in locations without power supply for trolley movement

·Suitable for short-distance or occasional movement

Typical Applications

·Workshops with limited budget

·Repair stations

·Short monorail operations

Low-frequency or occasional horizontal movement needs

Advantages

·Affordable and easy to install

·Great for environments where travel motor power is not available

·Useful for temporary or mobile workstations

Limitations

·Manual pushing requires operator effort

·Not ideal for long distances or heavy loads

·Slow movement compared to electric trolleys

Choose this type when frequent lifting is required, but horizontal travel is light-duty, short-distance, or low-frequency.

3. Electric Trolley Electric Chain Hoist

An electric trolley hoist provides powered horizontal travel along with electric lifting. This is the most efficient configuration for facilities requiring frequent or continuous movement of loads.

Key Features

·Motorized travel for smooth and consistent movement

·Optional single-speed, dual-speed, or VFD variable-speed controls

·Suitable for overhead cranes, gantry cranes, monorails, and production lines

·Designed for high-frequency, long-distance material handling

Typical Applications

·Manufacturing plants

·Steel structures & fabrication workshops

·Warehousing & logistics centers

·Automated production lines

·Gantry crane & overhead crane systems

Advantages

·Excellent efficiency and productivity

·Reduces operator fatigue

·Smooth, precise movement

·Ideal for continuous production environments

Limitations

·Higher cost than manual trolleys

·Requires power supply along the beam

·More components → higher maintenance demand

Choose this type for long travel distances, high-frequency use, and industrial production operations requiring efficiency and safety.

4. Low-Headroom Electric Chain Hoist

A low-headroom hoist is specially designed to minimize the distance between the hoist and the beam, maximizing lifting height. In this configuration, the hoist body and trolley are integrated into a compact structure.

Key Feature

·Optimized lifting height in limited headroom environments

·Compact design allowing higher hook position

·Available in electric trolley models

·Commonly used in buildings where standard hoists waste lifting height

Typical Applications

·Workshops with low ceilings

·Older buildings undergoing equipment upgrades

·Production areas with structural beams, pipes, or HVAC obstructions

·Single-girder overhead cranes requiring maximum lifting height

Advantages

·Best lifting height utilization

·Perfect for retrofits or constrained spaces

·Same lifting performance as standard electric hoists

Limitations

·Slightly higher cost than standard electric trolley hoists

·More complex structure

Choose this type when your building height is limited and every centimeter of lifting height matters.

5. Detailed Comparison of Hoist Types

Feature | Fixed Hoist | Manual Trolley Hoist | Electric Trolley Hoist | Low-Headroom Hoist |

Horizontal Travel | None | Manual | Motorized | Motorized |

Best for | Vertical lifting only | Short & occasional movement | Long, frequent movement | Low ceiling, limited headroom |

Cost | Low | Low–Medium | Medium–High | Medium–High |

Efficiency | Medium | Medium | High | High |

Installation Space | Very small | Moderate | Moderate | Smallest |

Ideal Load Range | 0.5–5 tons | 0.5–3 tons | 0.5–5 tons | 0.5–5 tons |

Maintenance | Minimal | Minimal | Moderate | Moderate |

6. How to Choose the Right Electric Chain Hoist

To make the best selection, evaluate the following key factors:

A. Do You Need Horizontal Movement?

No horizontal travel

→ Choose Fixed Hoist

Yes, but only occasionally or short distance

→ Choose Manual Trolley Hoist

Yes, long distance or frequent movement

→ Choose Electric Trolley Hoist

B. Is Building Height Limited?

Yes → Choose Low-Headroom Hoist

No → Standard hoist or trolley models are suitable

C. What Is Your Required Frequency of Use?

Low duty cycle → Manual trolley or fixed type

Medium duty cycle → Standard electric trolley hoist

High duty cycle / production lines → Electric trolley with VFD control

D. What Is Your Budget?

Tight budget → Fixed or manual trolley

Mid-range budget → Standard electric trolley

High-performance requirement → Low-headroom or VFD-equipped hoists

E. What Is the Load Capacity and Lifting Height?

Electric chain hoists typically excel in:

0.5–5 tons capacity

Simple, repetitive operations

Short to medium lifting heights

For heavier loads (5 tons+), electric wire rope hoists may be required.

F. Environmental Conditions

Choose enhanced protection if your environment includes:

High humidity or outdoor use → corrosion-protected models

Dusty or explosive atmospheres → explosion-proof hoists

Food or medical environments → stainless steel options

7. Customization Options

Electric chain hoists can be equipped with additional features:

Dual-speed or VFD frequency control

Overload limiter

Emergency stop

Upper and lower limit switches

Chain bucket (steel or fabric)

Wireess remote control

Motor soft-start system

Anti-sway control (for advanced systems)

These options improve safety, operating smoothness, and long-term durability.

Conclusion

Each type of electric chain hoist serves a different purpose. Fixed hoists are ideal for stationary lifting, manual trolleys suit light and infrequent movement, electric trolleys excel in production environments, and low-headroom hoists maximize vertical lifting in confined spaces. By understanding your lifting capacity, frequency of use, movement needs, and workspace limitations, you can choose the most cost-effective and reliable hoist solution.

This comprehensive guide helps industrial users and buyers make better decisions when selecting the most appropriate electric chain hoist for their operation.