Maintenance and maintenance of electric chain hoist

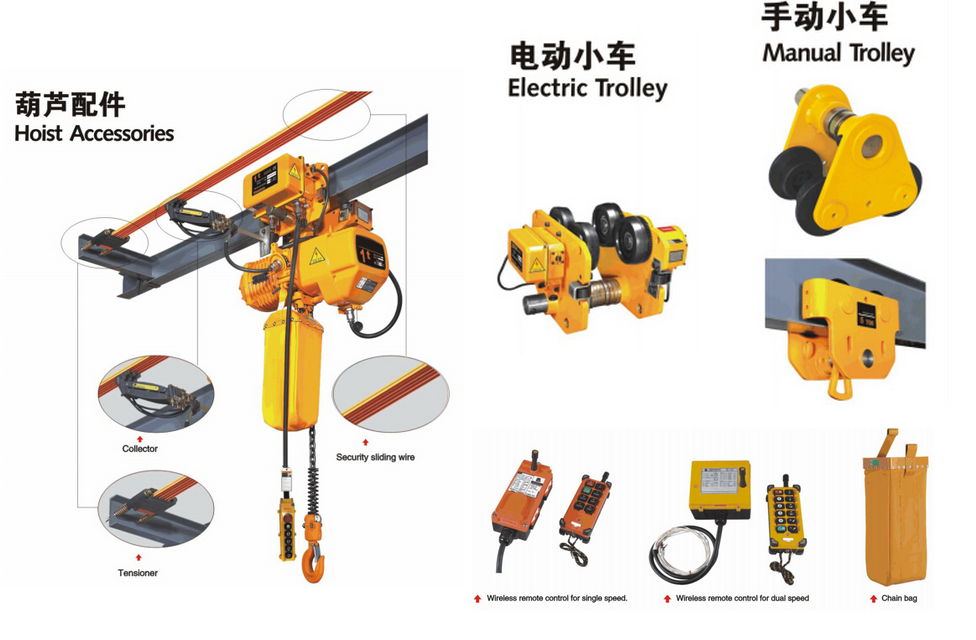

The chain of the electric chain hoist is made of low-carbon alloy steel, which makes the chain more tough, stronger and more wear-resistant, ensuring safety during work. The chain of the electric hoist can also be lengthened and customized according to customer requirements, making it more convenient and worry-free for you to use. The chains of imported electric hoists are equipped with chain bags, which make the electric hoist look clean and tidy. The chain bags are also equipped with anti-rust oil so that the chain is not easy to rust, thereby extending the service life of the electric hoist. Two complete and independent brake systems not only reduce the possibility of brake failure, but also enhance brake safety and facilitate heat dissipation.

1. Electromagnetic brake

The new brake system reacts quickly and provides positive braking force. The use of non-asbestos brake linings greatly extends the maintenance cycle. The brake system has been tested more than once.

2. Mechanical brake

Very reliable mechanical brakes and electromagnetic brakes coordinate with each other, which can stop the machine at any time. The relay can protect the hoist from damage caused by the wrong connection (reverse connection) of the power cord. Easy to maintain

The steel structure design of the electric chain hoist simplifies the maintenance and replacement of parts, which is a great advantage of the electric chain hoist. The use of limit switches can eliminate the damage caused by overload and low load to the hoist.